The Pre-Production Inspection (PPI) is a quality control conducted before starting the production to assess the quantity & quality of the raw material & components whether they are in conformity with the product specification. We following These steps of Pre-Production :-

- Raw material & accessories check.

- Style,colour & workmanship check.

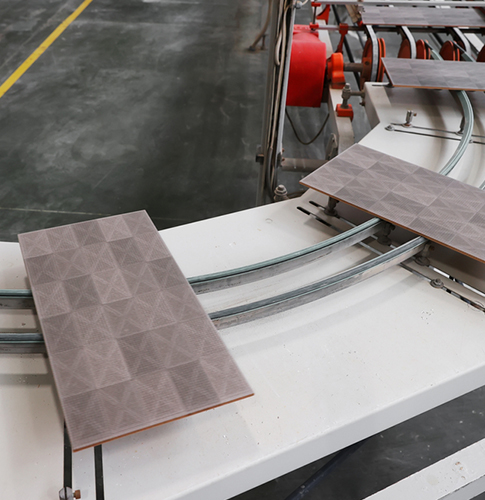

- Photos of production line & environment.

- Analyze the factory's production & quality control ability.